One horizontal element CD 375mm long. L bracket design calculation Guide to Design Criteria for Bolted and Riveted Joints.

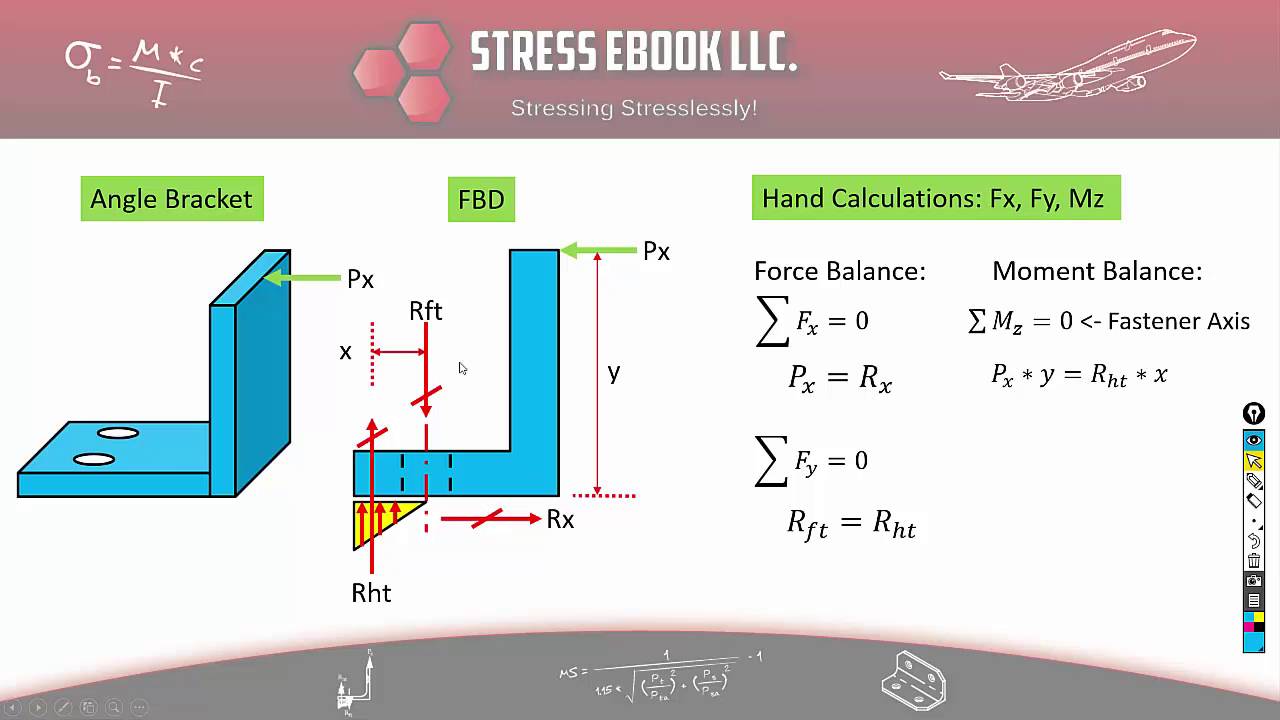

Angle Bracket Combined Loading Youtube

L bracket stress calculation.

. Flora and fauna recycling. L Bracket Design Calculation. Physical and Mechanical Properties Ultimate Tensile Strength psi 45000 Yield Strength psi 40000 Brinell.

Bracket which can be less or more than the width of the compressor. L bracket design calculation. CD is fixed at 90deg to AB 130mm from the top.

Design of a Rigid Column Bracket Welded Determine the size of the components required to connect the bracket to the column shown in figure below using Grade S355 steel. Cantilever Bracket Calculations. L bracket design calculation.

Lets say that I would like to utilize a L 5 x 3 12 x 38 bracket to support a vertical load laying evenly on top of it. Its free to sign up and bid on jobs. The forces shown are applied to one gusset plate at ultimate load.

Bolts and base of the compressor may have shape which will help us bolting the compressor to the plate. Thursday July 2 2015. This leads to shape of side closed L bracket Dimension of the bracket.

I think it best to first understand the functionality then look for the weakest link in the design. Wh312 1 0253 12 0001302083. Moment of inertia of a rectangle.

L bracket design calculation Coffin nails have gotten the hottest manicure pattern at the moment thats heading nowhere swiftlyBlack seems to be great with any colorHowever it doesnt enable it to be any much less beautiful. Consider the bracket shown in Fig. This ratio is called the Stress Concentration Factor and is discussed below.

L bracket design calculation. Mexican food truck atlanta. One vertical element AB 330mm long with a fixing at either end to a wall.

I have a cantilever bracket fixed at one end free at the other. The steel angle bracket is to be supported at both ends by means of other two sets of angle brackets vertical positioned which are to be attached to I-Beams. The safe load â The shelf will be 30 inches deep trying it with a 025 inch thick steel bracket that is 1 inch wide supported at one end the wall and with a load of 1 pound at the far end of the shelf.

Figure 1 90 angle bracket with a rib - nailing pattern. The sliding bracket will rotate clockwise due to the eccentrically applied load. Length of Side 2 Bend Length Material Thickness Inside Bend Radius 150.

Moment of inertia of a rectangle. Design Examples V140 AMERICAN INSTITUTE OF STEEL CONSTRUCTION iii PREFACE The primary objective of these design examples is to provide illustrations of the use of the 2010 â Structural Design of a Glass Facade Parts Design Beam Deflection on. The cantilever length and.

The T-stub characteristics areleff 458333 mm As 480 mm² m 50 mm and Lb 150 mm short anchor bolts Figure 4b Lb 300 mm moderate anchor bolts Figure 4c Lb 600 mm long anchor bolts Figure 4d while the nm ratio takes the following values. Search for jobs related to L bracket design calculations or hire on the worlds largest freelancing marketplace with 20m jobs. Ad Find Deals on l brackets 12 inch in Hardware on Amazon.

December 30 2021 inflatable bathtub walmart. Here is a picture of the bracket that I designed and I am thinking about making it with 14 inch 6061 aluminum with the following properties. A constant downward load W30kg is applied to the end of CD l375mm.

Direction of forces relative to the supporting beam and the purlin The characteristic load-carrying capacities Fk are intended to be used for the calculation of the design. For a tubular shaft J p2 R 4 - r 4 where r is the inner radius. Up to 24 cash back Example 5.

Da mango pomelo sago boba giovedì 30 dicembre 2021 Pubblicato il apostrophe at the end of a word examples. The objective of this analysis is to determine the weld size S that results in a maximum throat stress of 13. The shelf will be 30 inches deep trying it with a 025 inch thick steel bracket that is 1 inch wide supported at one end the wall and with a load of 1 pound at the far end of the shelf.

Consider the L-bracket shown in Figure 9. Analysis of weld group The total length of weld Lw 2dw bw 2400 200 1200 mm. Wh312 1 0253 12 0001302083.

Length of Side 1 Bend Length Material Thickness Inside Bend Radius 050 0048 0025 0427 Step 2. A 20 mm thick 700 mm wide shelf supports. L bracket design calculationartisanal museum wrap on fine wood L.

Hi I am a Computer Engineer who may be in a little over my head in producing my own brackets for a shelving project I am working on. Assuming centre of pressure 25 mm below top of cleat point A horizontal shear force on bolt due to moment due to eccentricity e 150 502 20050212522002 129 kN V2exri ri2 vertical shear force per bolt 1506 250 kN resultant shear 12922502 2813 kN. L bracket design calculation.

L bracket design calculation. Wl3 3EI 1303 3290000000001302083 0238344797. The outer RHS linear bearing will carry all the load plus the negative load on the inner LHS linear bearing.

On experimental and existing conventional calculation efforts. Figure 25 Simple L-Bracket Part Bend Formula for a L-bracket Step 1.

Mechanical Design Tutorials On Basic Calculations Bright Hub Engineering

Angle Bracket Horizontal Load Heel Toe Youtube

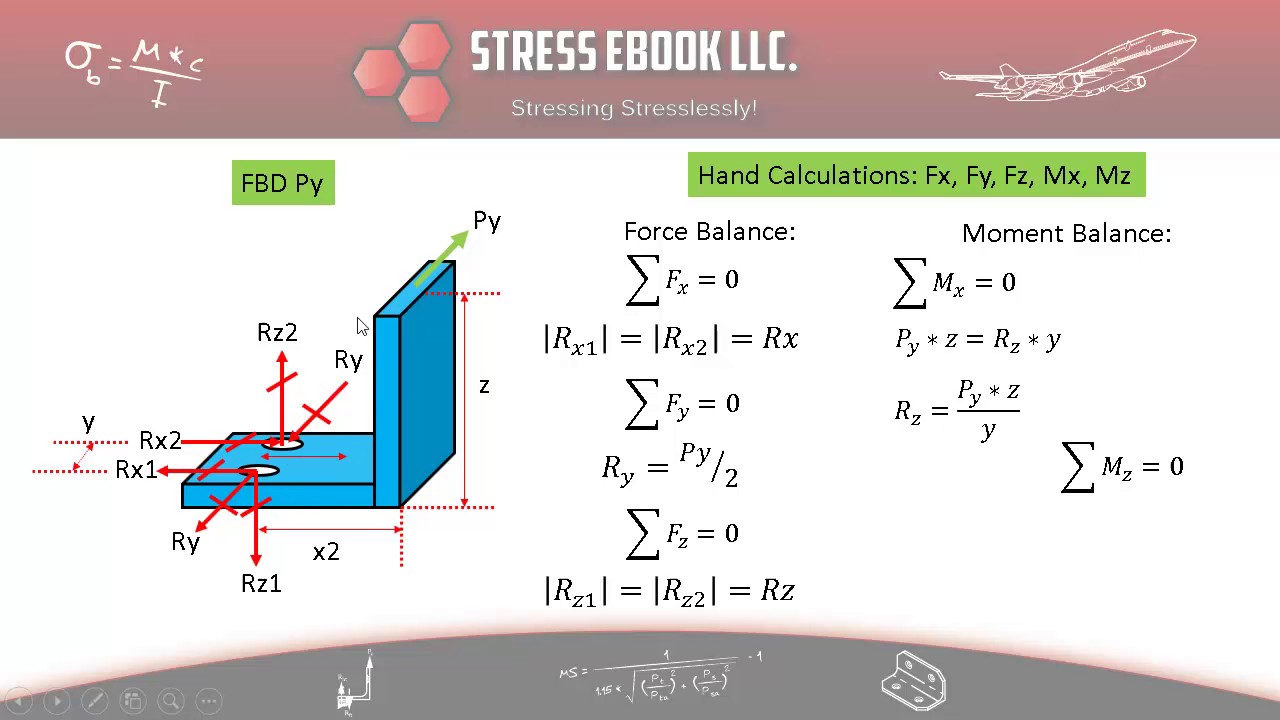

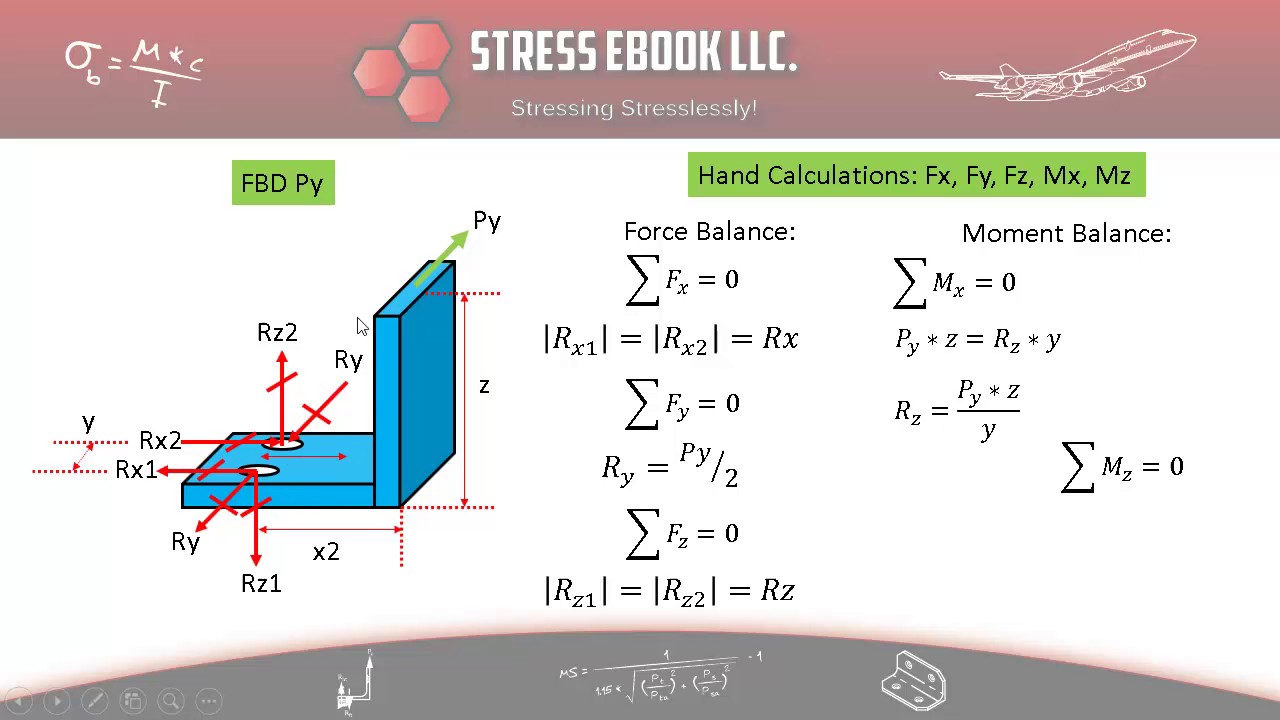

Angle Bracket Combined Loading Youtube

Angle Bracket Sizing And Stress Analysis Stress Ebook Llc

Mechanical Engineering Ch 11 Friction 8 Of 47 Bracket On A Pipe Youtube

Angle Bracket Sizing And Stress Analysis Stress Ebook Llc

Mechanical Design Tutorials On Basic Calculations Bright Hub Engineering

Pull Away Load On L Bracket Top Leg Hand Calculation Finite Element Analysis Fea Engineering Eng Tips

0 comments

Post a Comment